NORSCAND® and Geothermal Projects.

DRIVING SUSTAINABLE VALUE

A Proven Path to Sustainable Lithium.

Geothermal projects present an opportunity to extract lithium from the earth with a minimal physical footprint and carbon footprint. This comes from having access to a continual stream of geothermal fluid saturated with salts, coupled with renewable electricity coming from the geothermal turbines. The combination of geothermal power, direct lithium extraction and electrolysis make net zero lithium a possibility, delivering ESG benefits for clients and project financers alike.

HAND IN HAND

Collaborate with NESI.

NESI supports geothermal lithium projects at all development stages. We evaluate your geothermal brine’s compatibility with our electrolysis process to enhance lithium recovery. Our team integrates our technology into your existing infrastructure to maximize efficiency.

We provide pilot and demonstration-scale electrolyzers to validate the process and collect essential project data. NESI also offers support for scaling up to commercial production, including equipment design, installation, and ongoing assistance.

OUR TECHNOLOGY

Built for the needs of your operation.

Greenfield Developments

Minimize your environmental impact with reduced water consumption and significantly less effluent, ensuring smoother project approvals and faster timelines. Backed by decades of experience in large-scale industrial projects, we’ve got the expertise you need to succeed.

Geothermal

NESI’s technology integrates with Direct Lithium Extraction (DLE), allowing you to produce sustainable lithium from geothermal brines. Limit land disturbance and water usage while generating clean energy and achieving a near-zero carbon footprint for lithium production.

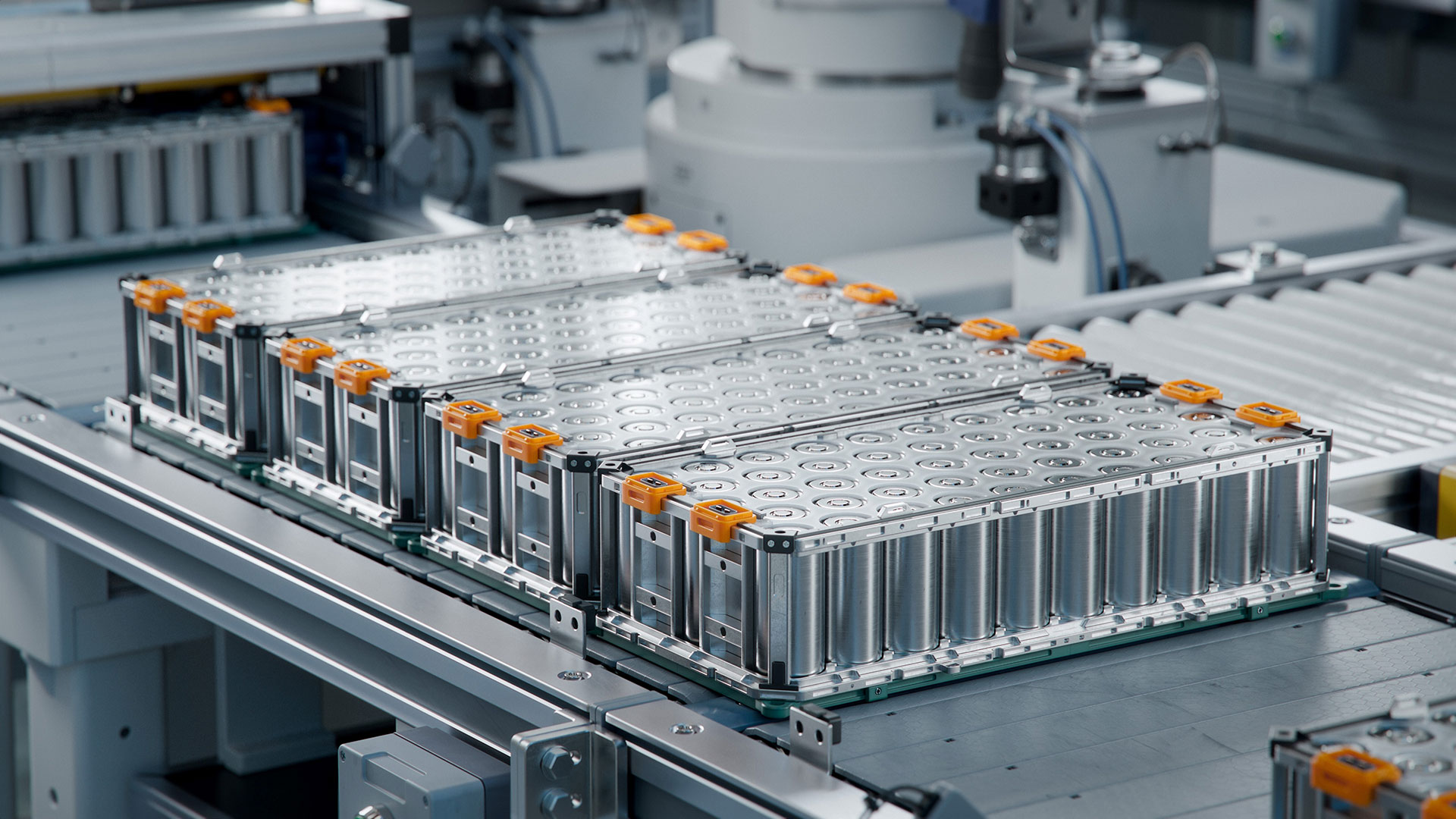

Recycling

Recycling lithium-ion batteries should be simple. Our low-waste, low-carbon technology reduces the environmental impact of battery recycling, maximizes resource recovery and supports a circular economy.