15 YEARS OF LITHIUM TECHNOLOGY ADVANCEMENT

The NORSCAND®Electrolyser.

UNLOCKING LITHIUM’S POTENTIAL

The Power of Purity with the NORSCAND® Electrolyser.

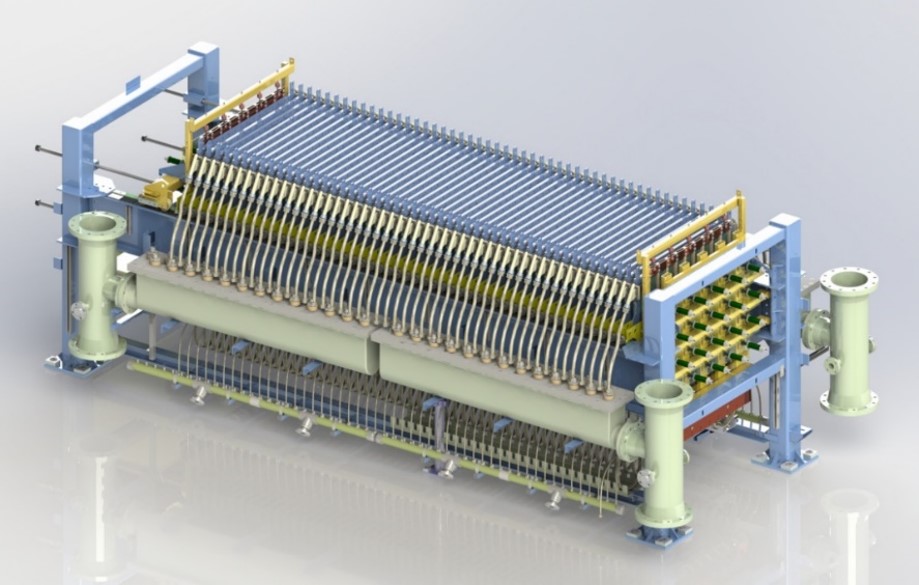

The NESI’s NORSCAND® electrolyzer is a cutting-edge technology with a long history of development and success. This proprietary electrochemical cell has been commercially proven for the electrolysis of lithium chloride and lithium sulphate brines, producing high-purity lithium hydroxide. The NORSCAND® electrolyzer uses salt splitting, which separates lithium salts into their constituent ions using an electric current. This method efficiently produces high-purity lithium hydroxide that meets the stringent requirements of the lithium-ion battery industry.

LEGACY OF INNOVATION

Advanced Lithium Electrolysis Technology.

We have been developing and refining the NORSCAND® electrolyzer for over 15 years, drawing on our deep expertise in industrial electrochemistry and scaling up novel electrochemical processes since 1999. Our team has engineered a high current density, bi-polar design featuring a substantial 1.5 m² electrode area. The anode utilizes a titanium expanded metal mesh, offering the flexibility of a DSA-O2 or DSA-Cl2 coating, depending on specific process requirements. The cathode is constructed from stainless steel or nickel-expanded metal mesh.

The NORSCAND® A15 system’s modular design allows for configurations ranging from 1 to 100 cells per electrolyzer stack. This scalability ensures that our technology can adapt to your specific operational needs.

PROVEN RESULTS

Testing the Limits.

NESI operates a world-class commercial demonstration facility at BC Research in Vancouver, a state-of-the-art lithium electrolysis test center designed for full-scale testing and validation of our NORSCAND® technology. This fully instrumented facility is staffed with a multidisciplinary team of skilled scientists and engineers. Using commercial-sized NORSCAND® cells, we conduct rigorous testing on various industrial brines.

We focus on determining optimal brine treatment requirements, accurately modelling process performance and durability, and ultimately engineering and scaling facilities for efficient commercial production. Beyond testing, we provide guidance on upstream and downstream processes to guarantee the smooth integration of our technology into your existing operations.

A HOLISTIC APPROACH

The Complete System.

The success of electrochemical processes goes beyond the availability of an electrochemical cell. The entire electrolysis system design is critical to the successful operation of the cell, the lifetime of the coatings and membrane, and overall process economics. NESI provides state-of-the-art electrochemical cells with the corresponding DC power systems and develops the processes essential to the proper operation of electrochemical systems. This includes process requirements, mechanical and piping requirements, control systems, and materials of construction selection. NESI has been working in the industrial electrochemical space for over 30 years and has developed core engineering competencies in the following areas:

- Electrochemical Cell House Design, Layout, and Operations

- Design of Customized Cell Stacks for Specific Electrochemical Processes

- Electrolyte Chemistry and Management

- Brine Impurity Control

- Power Electronics and Control

- Hydrogen and Chlorine Gas Handling

- Materials of Construction

- Operational Safety and Codes

THE FUTURE OF LITHIUM STARTS HERE

Partnering for Progress. Connect with Our Team.

If you’re looking for a sustainable solution for lithium conversion, treating and recovering chemical value from waste streams, or looking to develop a novel electrochemical process technology, there’s a good chance that we have the experience, engineering expertise, and technology portfolio to accelerate your project.