NORSCAND® and Recycling Projects.

REIMAGINING RESOURCES

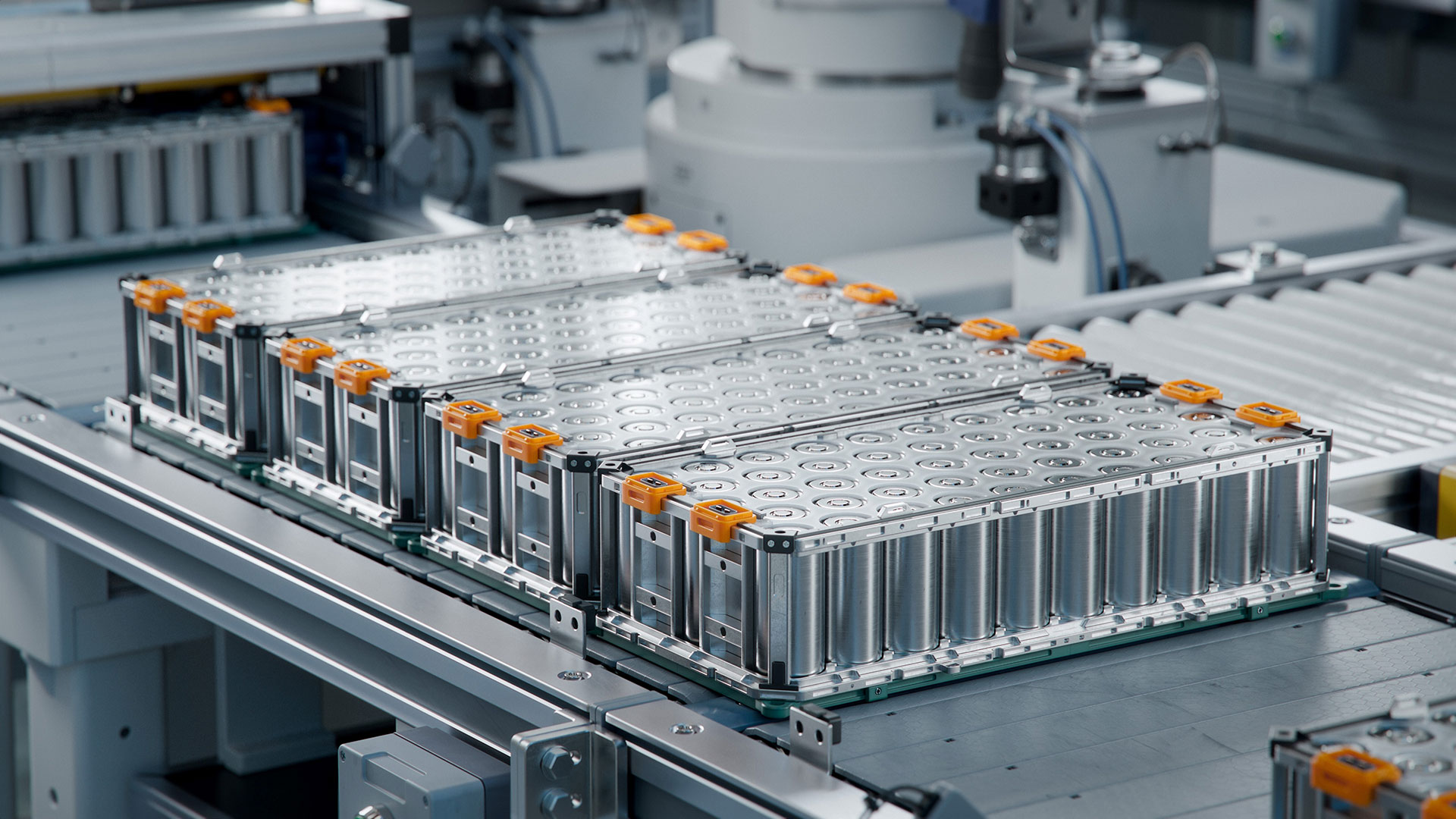

Closing the Loop on Lithium.

NESI’s process minimizes the use of harsh chemicals, reducing the environmental impact of recycling operations. Our technology enables high lithium recovery rates, maximizing the value of recycled materials. NESI specializes in integrating process recycle loops to reduce upstream reagent needs and optimize lithium recovery. Our extensive experience in upstream lithium processing gives us a deep understanding of the complexities of recycling black mass and other lithium-containing materials.

SETTING THE STANDARD

Leading the Way in Electrochemical Innovation.

We’ve been at the forefront of industrial electrochemistry for decades, with a proven track record of scaling up novel electrochemical processes. Our experience includes industrial electrochemistry expertise since 1990, scaling up novel electrochemical processes since 1999, with over 20 processes scaled up, scaling up lithium salt electrolysis processes since 2006, and the first-ever demo scale (250 TPY) lithium electrolysis in 2017, with 30 months of operation.

OUR TECHNOLOGY

Built for the needs of your operation.

Greenfield Developments

Minimize your environmental impact with reduced water consumption and significantly less effluent, ensuring smoother project approvals and faster timelines. Backed by decades of experience in large-scale industrial projects, we’ve got the expertise you need to succeed.

Geothermal

NESI’s technology integrates with Direct Lithium Extraction (DLE), allowing you to produce sustainable lithium from geothermal brines. Limit land disturbance and water usage while generating clean energy and achieving a near-zero carbon footprint for lithium production.

Recycling

Recycling lithium-ion batteries should be simple. Our low-waste, low-carbon technology reduces the environmental impact of battery recycling, maximizes resource recovery and supports a circular economy.