NORSCAND® and Greenfield Projects.

CREATING VALUE SUSTAINABLY

The NESI Advantage.

NESI’s lithium electrolysis process offers significant benefits for greenfield projects. It reduces or eliminates the need to transport concentrated chemicals, minimizing community disruption and concerns over hazardous materials. Our clean approach prevents toxic waste generation, protecting local ecosystems and water resources. By promoting clean products like electric vehicles and improving the supply chain, your project supports a sustainable future, enhancing community support and regulatory approval.

Unlike traditional methods, our process decreases reliance on complex chemical supply chains and waste disposal, reducing operational risks and ensuring a more predictable project timeline. With our “just add electrons” philosophy, we minimize environmental impact by eliminating harsh chemicals and harmful waste, leading to lower carbon emissions and reduced water usage.

HAND IN HAND

Collaborate with NESI.

We offer comprehensive support throughout the lifecycle of your greenfield project. We can test your specific brine at both pilot and full demonstration scales at our state-of-the-art Richmond facility. This allows for accurate data collection and process optimization tailored to your unique resource.

NESI can help you develop detailed capital expenditure (CapEx) and operating expenditure (OpEx) estimates for your lithium refinery project, providing you with the financial clarity needed for informed decision-making. We design, quote, and deliver pilot and demonstration-scale equipment that allows you to validate the electrolytic process on-site and de-risk your project before full-scale deployment. We provide expert guidance on integrating our electrolysis technology with your upstream and downstream processes, ensuring an optimized flowsheet.

OUR TECHNOLOGY

Built for the needs of your operation.

Greenfield Developments

Minimize your environmental impact with reduced water consumption and significantly less effluent, ensuring smoother project approvals and faster timelines. Backed by decades of experience in large-scale industrial projects, we’ve got the expertise you need to succeed.

Geothermal

NESI’s technology integrates with Direct Lithium Extraction (DLE), allowing you to produce sustainable lithium from geothermal brines. Limit land disturbance and water usage while generating clean energy and achieving a near-zero carbon footprint for lithium production.

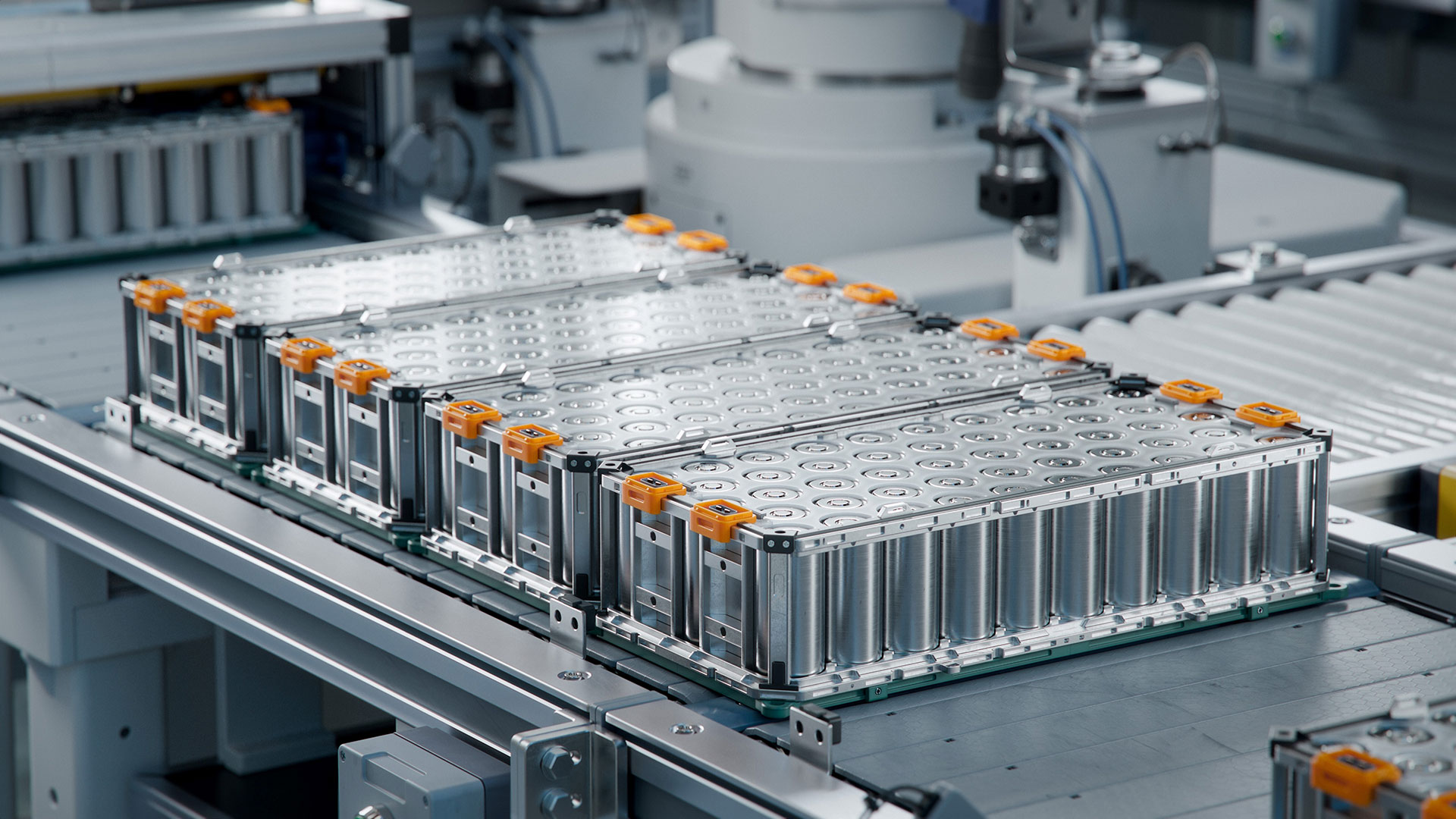

Recycling

Recycling lithium-ion batteries should be simple. Our low-waste, low-carbon technology reduces the environmental impact of battery recycling, maximizes resource recovery and supports a circular economy.